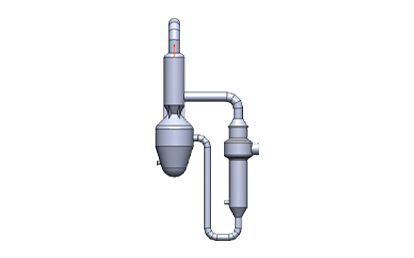

The working principle is that the material is driven by the circulating pump in the heat exchange tube of the tubular heat exchanger, and flows at a certain flow rate. During the flow process, the heat released by the steam condensation outside the pipe is absorbed, and the material temperature increases but no phase change (vaporization) occurs in the heating pipe. When the material enters the flash steam chamber, the material can be concentrated. Because the material does not change (steam) in the heat exchange pipe, the concentration of the material in the pipe does not change, and will not produce crystallization and scaling. Therefore, it can fully resist scale and crystallization, which is suitable for the concentration of liquid that is easy to produce scaling and crystallization. Because the materials flow in the pipe, it is not easy to block, so it is especially suitable for the evaporation of suspended matter and high viscosity and high concentration fluid.

Corn slurry, alcohol waste liquid, lysine waste liquid, glutamate waste liquid, carrier fermentation liquid, yeast waste liquid, penicillin waste liquid all kinds of chemical wastewater.

Vc, citric acid, lysine, threonine and other amino acids, sodium chloride, ammonium chloride, ammonium sulfate, sodium sulfate, magnesium sulfate, sodium phosphate, sodium carbonate, ammonium carbonate, sodium nitrate, lithium hydroxide, lithium carbonate.

It is suitable for the concentration of liquid prone to produce scale and crystallization; it is not easy to plug, so it is especially suitable for the evaporation of suspended matter and high viscosity and high concentration fluid.

Oslo crystallization is suitable for the crystallization of citric acid, lysine organic matter and the crystallization of NaCl, NaCrO7, NaHCO3, NaCO 3 · 2H2O, (NH 4) 2SO4, NH4NO3, etc.

|

产品规格 |

晶体产量 |

蒸发水量 |

耗气量 |

装机容量 |

备注 |

|

0.5t/h |

0.5t/h |

0.5t/h |

Kg/t水 |

Kw |

|

Shandong Lemon Biochemical Co., Ltd

COFCO

.jpg)

COFCO