In the Forced-cycle evaporation / crystallization system, the material flows through the circulating pump at a rate of 1-3 m / s, heating by 1-5°C. The state of slurry and easy scaling material in the evaporator heat exchange pipe is equivalent to their motion state of the same size pipe and the same flow rate, and the effect of a small amount of temperature change is not obvious. That is to say, under the same conditions, if the material can pass through a pipe, it can pass through the heat exchange pipe of the evaporator. The specification of the forced circulation system is much higher than that of the lower film system; for the crystallization, the lift required of the circulating pump is very low. The anti-scaling ability of forced circulation evaporation system is stronger than that of lowering film system, and it is suitable for the concentration or continuous crystallization of materials easy to scale.

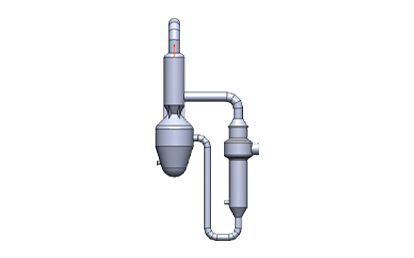

According to the characteristics of evaporating materials, two forms of falling film and forced circulation can be combined in the design to deal with scaling materials and continuous crystallization system. Complete the pre-concentration of materials in the lower film unit, and then enter the forced cycle unit to complete the final concentration or continuous crystallization, saving the equipment input and operation costs.

It has the advantages of wide range of concentrated materials, large concentration ratio, high discharge concentration, sufficient resistance to scale accumulation and blockage resistance.

process flow

Typical paradigm of enrichment use

Corn slurry, alcohol waste liquid, lysine waste liquid, glutamate waste liquid, carrier fermentation liquid, yeast waste liquid, penicillin waste liquid all kinds of chemical wastewater.

Typical paradigm of crystallization use

Vc, citric acid, lysine, threonine and other amino acids, sodium chloride, ammonium chloride, ammonium sulfate, sodium sulfate, magnesium sulfate, sodium phosphate, sodium carbonate, ammonium carbonate, sodium nitrate, lithium hydroxide, lithium carbonate.

Guangxi Xintiande

State investment chicken east

Jilin Modern Tianfeng

Longsheng ammonium sulfate

Yihai Kerry

Zhejiang Shuyang organic acid