Waste Heat Evaporator is an evaporation system that uses waste heat to provide effective heat transfer temperature difference. In chemical industry, light industry, food and other factories, the production process will always produce a certain amount of low quality waste heat, such as starch factory byproducts (fiber, protein, germ) and alcohol factory DDGS drying of secondary steam and condensate, alcohol distillation of alcohol steam and waste liquor, sugar liquid and liquid, and other intermediate products carry heat or latent heat, through reasonable design can be reused in the evaporation system. Liquid waste heat can be preheating the material using its explicit heat, or flash steam to use its latent heat; steam waste heat can directly use its latent heat.

Waste heat evaporator can be designed to use many kinds of waste heat together, or to mix waste heat and steam to use different temperatures; waste heat can be used once or several times. According to the utilization degree of waste heat, the waste heat evaporator can use less or even no raw steam, which can greatly reduce the operating cost of the evaporator and the energy consumption of the factory, and greatly reduce the carbon, dust and waste gas emissions of the factory.

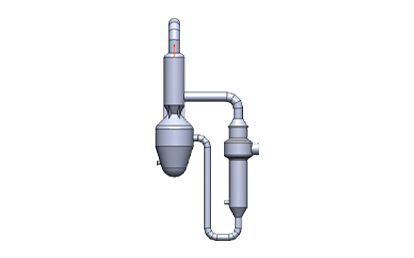

Concentrate of corn pulp, alcohol waste mash, process wastewater, glucose and other materials.