GZG Tube Dryer is an indirect contact drying equipment with a fixed housing. The steam enters the heat transfer pipe through the rotating joint and becomes condensed and discharged. The material is lifted by the rotating material shovel in the pipe bundle dryer and falls evenly to the surface of the heat exchange pipe. After the moisture of the material is heated outside the heat of the heat exchange pipe, the steam is discharged from the dehumidification fan, and the dry material is pushed from the material shovel to the outlet and discharged.

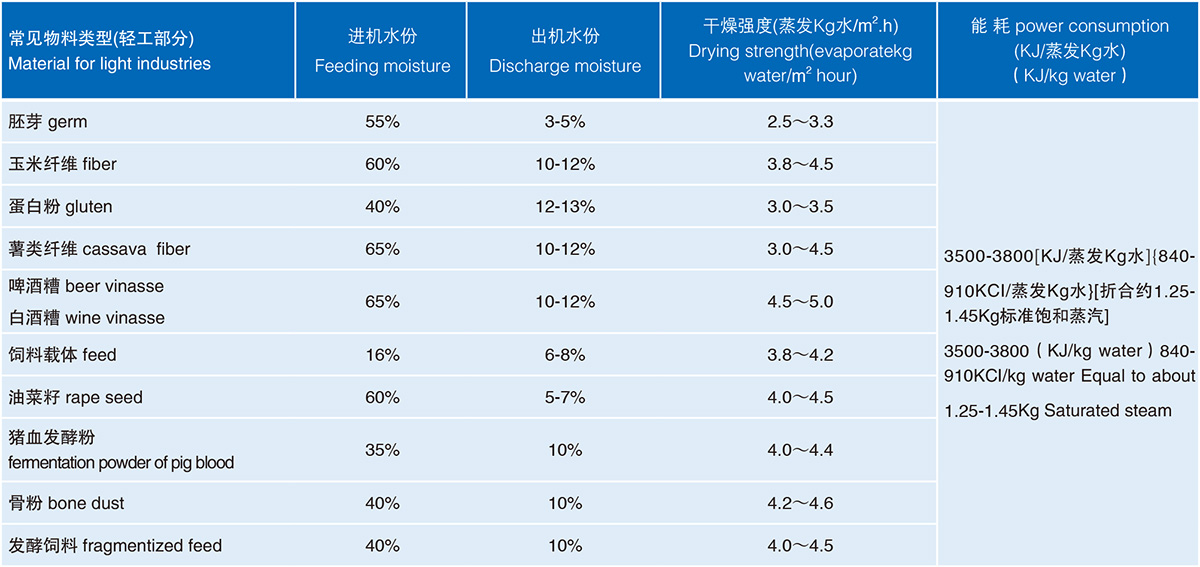

A wide range of dry materials

Good energy saving

Water evaporation is large, and can be continuously production

Dry under negative pressure, dust does not overflow, no workshop dust, health, safety

High degree of automation, automatic control of steam intake, fan speed, dragon anti-blocking detection and alarm, host and dragon running status alarm and interlocking

Pipe bundle dryer is widely used in chemical industry, light industry, food and feed (example: wine grains feed DDGS) and other industries of loose wet material drying.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)