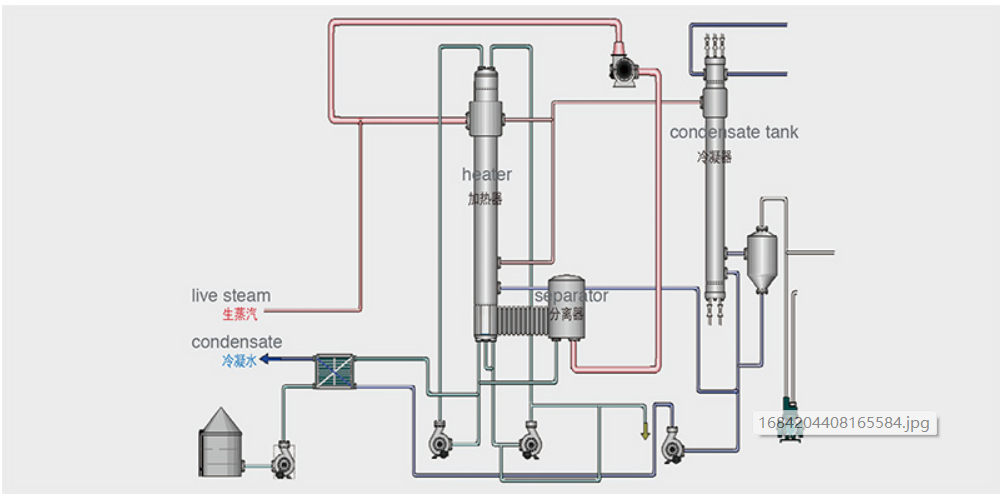

The MVR evaporation system uses a compression fan to compress and boost the secondary steam formed in the evaporation system. Increasing the condensation temperature of the compressed secondary steam can be used as the heat source for the evaporation system. Under appropriate conditions, the system does not need to replenish raw steam for evaporation; when the feed temperature is lower than the evaporation temperature of the system, when sufficient heat energy cannot be recovered from the concentrate and the condensate produced by the system, a small amount of raw steam should be added to preheat the material to the boiling point. Generally, the energy consumption of one ton of evaporated water compression fan is in the range of 15KW~30KW; according to the material characteristics, it will be lower or higher than this range.

No need to live steam

Low energy consumption, low operating cost

It can be combined with a crystallization to make a continuous crystallization in the form of MVR

|

The chemical and pharmaceutical industries |

|

|

ethyl alcohol |

Phenol, methanol, ethanol, butanol, glycerol, and ethylene glycol |

|

Pharmaceutical solution |

Enzymes, antimicrobials, pharmaceutical extracts, sugar substitutes, sorbitol, sorbitose, gluconate |

|

food industry |

|

|

dairy product |

Whole fat and skimmed milk, condensed milk, sweet whey and lactic acid, butter, milk protein, lactose solution |

|

High protein juice |

Soy whey, yeast extract, and feed yeast |

|

fruit juice |

Orange juice and other citrus juice, apple juice and other apple juices, mixed juice, tropical water juice |

|

vegetable juice |

Raw vegetable juice, beet root juice, tomato juice, carrot juice |

|

Starch products |

Glucose, dextrose, levanose, maltose, starch syrup, dextrin |

|

sugar |

Sugar beet sugar, liquid sugar, refined white sugar, sweet water |

|

extractive |

Meat and bone extracts, coffee and tea extracts, snake herb extract, malt extract, yeast extract, pectin |

|

Hydrolysis substances |

Whey hydrolysate, flavoring solution, proteollysate |

Potassium lactose chloride cyclic ethylene chloride sodium carbonate sodium nitrite ammonium bromide, citric acid, ammonium sulfate, potassium chloride, sodium chloride sodium hyperborate ammonium chloride copper chloride, magnesium chloride sodium dichromate sodium chloride sodium chloride sodium perchloride chloride sodium chloride sodium chloride sulfate sodium sulfate copper glucose sulfate sodium sulfate sodium sodium sulfate, sodium phosphate sodium chlorophenyl malate potassium phosphate, sodium chloride salicylate sodium ascorbate vitamin C sodium dichromate sulfate sodium bisphenol A diisopropyl ether acetate sodium salartrate sodium tartrate wastewater recovery sulfate Nickel nitrate, silver nitrate, sodium fluoride sodium thiocyanate calcium chloride ferryl eryththalol sodium acetate, sodium formate, zinc sulfate, calcium formate formate potassium bromide ascorte sodium, sodium glutamate acetyl salicylate sodium tartrate calcium glutamate, potassium carbonate, potassium nitrate copper saccharate ammonium, phohalogenite process flow

1.Ammonium chloride crystallization of penicillin wastewater from Sinopharm Group

2.Tobacco medium tobacco extract

3.Shandong Hda 32t / hMVR crystallization evaporator

4.Sodium sulfate wastewater in Jinghua

5.Portuguese yeast wastewater

6.Taiwan copper sulfate