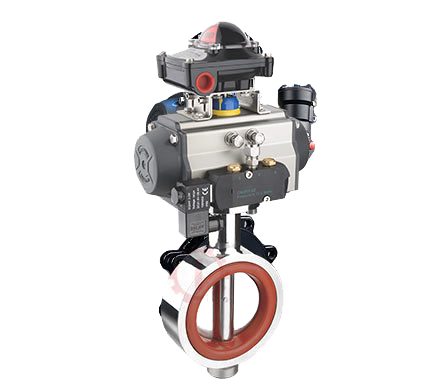

Pneumatic and sanitary grade butterfly valve, sealed, long service life, products inside and outside with high-grade polishing equipment treatment, to meet the surface precision requirements, widely used in beer, beverage, dairy, fruit juice, pharmaceutical, biological engineering and other fields.

1, the butterfly valve rubber sealing ring and the valve plate are imported, to ensure the service performance and service life of the butterfly valve.

2, the use of high-precision CNC lathe fine car valve body, to ensure the reliable interchangeability of the butterfly valve, from the replacement of rubber and can not guarantee the performance of the trouble.

3, the valve rod is equipped with nylon shaft sleeve, reducing the friction force and thus open flexible and easy.

4, steel parts are made of stainless steel, rubber using food rubber, high health quality.

5, the valve body diameter and the pipe inner diameter, opening narrow and streamlined valve plate and the fluid direction of the same, large flow and small resistance, no material accumulation.

6, the opening and closing range is 0~90 degrees, can be fixed at the position of every 15 degrees, with tunability, and rapid opening and closing, easy to operate.

7, the valve body is used for removable connection, simple structure, convenient maintenance.

8, the shape is light and beautiful, the surface is bright but not sticky dust, no burrs.

9. Sampling for fatigue life test of no less than 30000 times to ensure its service life.

Specification DN15- -DN150,1 "- -6"

Connection form: welding type, quick assembly type, thread type, clamp type, pair of clip type, etc

Drive mode: manual, worm worm gear transmission, air transmission, electric transmission

Standards: ISO, DIN, IDF, SMS, 3A, etc

Material: sus304, sus316L and other stainless steel materials

Sealing ring: EPDM, NBR, PTFE

Working pressure: 0.6Mpa, 1.0Mpa, 1.6Mpa

Operating temperature: -10℃ + 150℃

Applicable media: liquid, gas, oil products, various highly corrosive chemical media