D941X electric soft seal flanged butterfly valve as a new generation of speed regulating butterfly valve, the valve changes the traditional mode to complete the butterfly switch speed change from the mechanical variable speed. According to the action characteristics of different positions of the butterfly plate, a new design is carried out from the electric drive control. The electric soft sealing flange butterfly valve changes the frequency of the input current of the electric device, and then adjusts the rotation speed and output torque of the electric device, so as to control the start and closing speed of the butterfly plate and realize the purpose of fast closing or two stages of slow opening and fast opening. Has the same function as the liquid control butterfly valve.

Electric soft sealing flange butterfly valve is suitable for the pump outlet position of the pipeline with water and sea water. It is used as the closed valve and check valve to avoid and reduce the backflow and water hammer impact of the medium in the pipeline system and protect the pipeline. For power plants, water plants and other working power supply is very reliable occasions are especially suitable.

1. Electric opening and closing, with arbitrary adjustment, check and cut functions. Easy to operate, safe and reliable.

2. The valve can continuously realize the slow opening, fast opening, fast closing, slow closing action, and effectively prevent the pump outlet medium backflow and water hammer generation.

3. Energy-saving drive, the same drive motor as the ordinary butterfly valve can realize the function of fast close section high speed small torque and slow close low section large torque.

4. When installed at the pump outlet, the butterfly valve has the common function of check ah and gate valve at the same time, so one valve can be replaced with two valves to save the installation space and the cost of pipe network.

5. Small flow resistance. When the valve is not more than 0.3, so it can save energy and reduce the operation cost of the pipeline.

6. In case of an accident or power failure, the butterfly valve opening and closing can be controlled by manual operation.

|

公称压力(MPa) |

0.25 |

0.6 |

1.0 |

|

|

公称通经(mm) |

1000~2400 |

800~2400 |

500~1600 |

|

|

试验压力 |

强度试验 |

0.375 |

0.90 |

1.5 |

|

密封试验 |

0.275 |

0.66 |

1.1 |

|

|

适用介质 |

水、海水 |

|||

|

适用温度(℃) |

≤80℃ |

|||

|

安装方式 |

立式、卧式 |

|||

|

设计制造 |

法兰连接尺寸 |

结构长度 |

压力试验 |

|

GB/T 12238 |

GB/T 2555-2526-8 |

GB/T 12221 |

GB/T 13927 |

|

零件名称 |

材料 |

|

阀体 |

球墨铸钢、铸钢、合金钢、不锈钢 |

|

蝶板 |

灰铸铁、球墨铸钢、铸钢、不锈钢及特殊材料 |

|

密封圈 |

各种橡胶、聚四氟 |

|

阀杆 |

2Cr13、不锈钢 |

|

填料 |

O型圈、柔性石墨O |

|

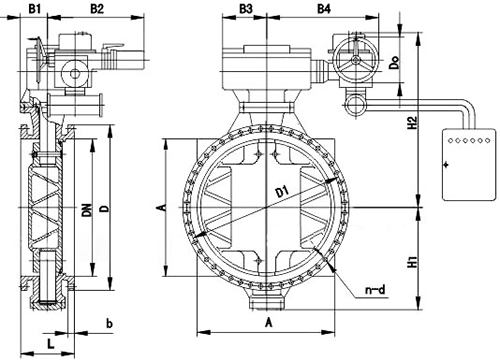

PN |

DN |

L |

A |

H1 |

H2 |

DO |

B1 |

B2 |

B3 |

B4 |

|

0.25MPa |

1000 |

410 |

|

817 |

1303 |

400 |

225 |

709 |

303 |

770 |

|

1200 |

470 |

1200 |

812 |

1529 |

400 |

225 |

709 |

303 |

760 |

|

|

1400 |

530 |

1400 |

1020 |

1692 |

400 |

225 |

728 |

303 |

760 |

|

|

1600 |

600 |

1600 |

1145 |

1885 |

400 |

275 |

843 |

385 |

778 |

|

|

1800 |

670 |

1800 |

1315 |

1924 |

400 |

275 |

879 |

385 |

792 |

|

|

2000 |

760 |

2000 |

1670 |

2095 |

400 |

275 |

969 |

450 |

856 |

|

|

2200 |

840 |

2200 |

1739 |

2487 |

400 |

430 |

1103 |

540 |

995 |

|

|

2400 |

910 |

2400 |

1699 |

2595 |

400 |

430 |

1103 |

540 |

995 |

|

PN |

DN |

L |

A |

H1 |

H2 |

DO |

B1 |

B2 |

B3 |

B4 |

|

0.6MPa |

800 |

318 |

|

667 |

1190 |

500 |

175 |

583 |

230 |

683 |

|

900 |

330 |

|

745 |

1245 |

400 |

225 |

709 |

303 |

770 |

|

|

1000 |

410 |

|

817 |

1303 |

400 |

225 |

709 |

303 |

760 |

|

|

1200 |

470 |

1200 |

912 |

1529 |

400 |

225 |

728 |

303 |

760 |

|

|

1400 |

530 |

1400 |

1041 |

1693 |

400 |

275 |

843 |

385 |

778 |

|

|

1600 |

600 |

1600 |

1145 |

1885 |

400 |

275 |

879 |

385 |

792 |

|

|

1800 |

670 |

1800 |

1346 |

1924 |

400 |

275 |

969 |

450 |

856 |

|

|

2000 |

760 |

2000 |

1670 |

2095 |

400 |

430 |

1103 |

540 |

995 |

|

|

2200 |

840 |

2200 |

1739 |

2487 |

400 |

430 |

1103 |

540 |

995 |

|

|

2400 |

910 |

2400 |

1850 |

2595 |

400 |

430 |

1103 |

540 |

995 |

|

PN |

DN |

L |

A |

H1 |

H2 |

DO |

B1 |

B2 |

B3 |

B4 |

|

1.0MPa |

500 |

229 |

|

548 |

943 |

500 |

145 |

533 |

162 |

610 |

|

600 |

267 |

|

583 |

985 |

500 |

175 |

583 |

230 |

683 |

|

|

700 |

292 |

|

612 |

1075 |

500 |

175 |

583 |

230 |

683 |

|

|

800 |

318 |

|

677 |

1190 |

400 |

225 |

709 |

303 |

770 |

|

|

900 |

330 |

|

745 |

1245 |

400 |

225 |

709 |

303 |

760 |

|

|

1000 |

410 |

|

817 |

1303 |

400 |

225 |

728 |

303 |

760 |

|

|

1200 |

470 |

1200 |

948 |

1529 |

400 |

275 |

843 |

385 |

778 |

|

|

1400 |

530 |

1400 |

1158 |

1692 |

400 |

275 |

879 |

385 |

792 |

|

|

1600 |

600 |

1600 |

1285 |

1885 |

400 |

275 |

969 |

450 |

856 |